In the realm of firefighting, the NFPA 1962 hose testing procedure stands as a cornerstone for ensuring the reliability and effectiveness of fire hoses. This comprehensive guide delves into the intricacies of hose testing, providing invaluable insights and practical steps to safeguard your firefighting equipment.

NFPA 1962 establishes clear guidelines for hose testing, covering various types of hoses and outlining the critical steps involved. By adhering to these standards, firefighters can ensure that their hoses meet the highest levels of performance and safety.

Overview of NFPA 1962 Hose Testing Procedure

NFPA 1962 is a comprehensive standard that provides guidelines for testing and maintaining fire hoses. Its primary purpose is to ensure the safety and reliability of fire hoses, thereby enhancing firefighter safety and operational effectiveness during firefighting operations.

NFPA 1962 covers various types of hose testing, including:

- Hydrostatic testing: This test involves subjecting the hose to high water pressure to assess its strength and integrity.

- Flow testing: This test measures the flow rate of water through the hose under specific pressure conditions.

- Pressure testing: This test evaluates the hose’s ability to withstand a specified internal pressure.

- Electrical testing: This test ensures that the hose is electrically safe for use.

Adhering to NFPA 1962 is crucial for several reasons:

- Ensures the reliability and performance of fire hoses, reducing the risk of hose failures during firefighting operations.

- Protects firefighters from potential injuries or fatalities caused by hose bursts or leaks.

- Maintains the integrity of fire hoses, extending their lifespan and reducing replacement costs.

- Provides a standardized approach to hose testing, ensuring consistency and accuracy in the evaluation process.

Preparation for Hose Testing

Before conducting hose testing, thorough preparation is crucial to ensure accurate results and minimize safety hazards. This involves preparing the hoses, observing safety precautions, and gathering the necessary equipment.

Safety Precautions

Prior to testing, implement the following safety measures:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Establish a designated test area that is clear of obstacles and potential hazards.

- Ensure the test site has adequate ventilation to prevent the accumulation of toxic fumes.

- Never stand directly in front of the hose when pressurizing or releasing water.

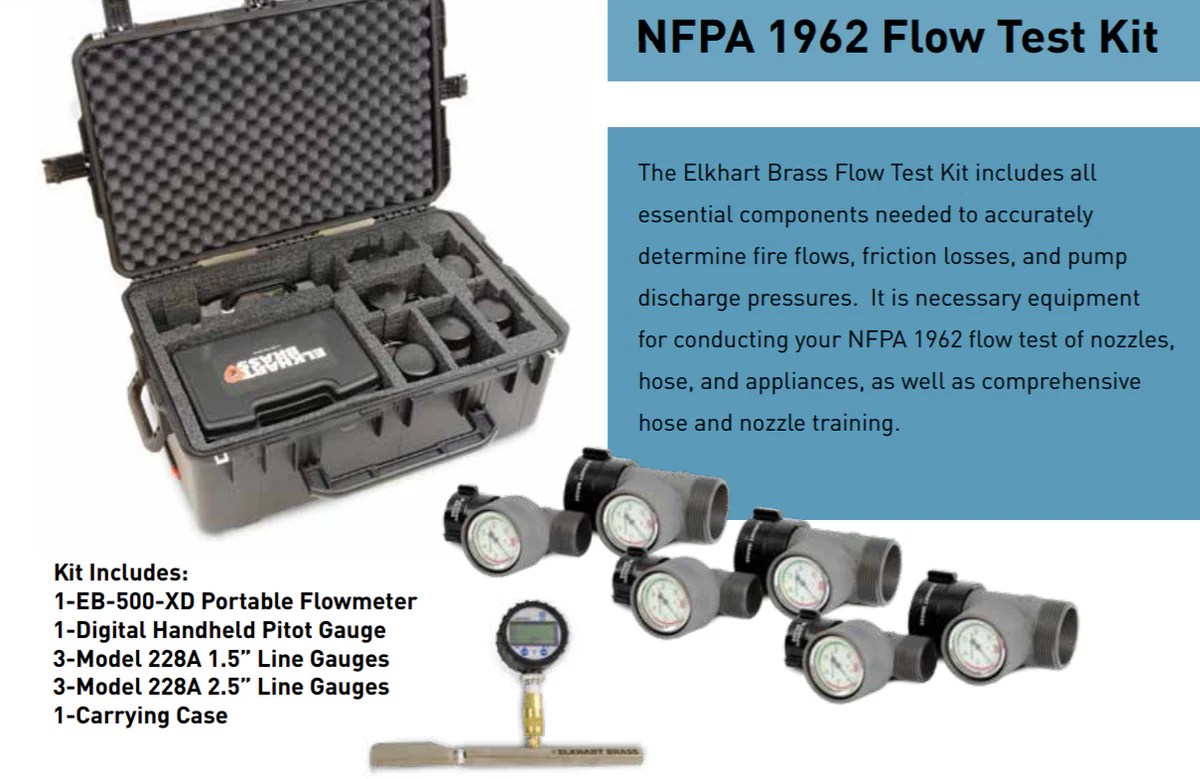

Equipment Required, Nfpa 1962 hose testing procedure

The following equipment is necessary for hose testing:

- Pressure gauge with appropriate range for the hose being tested

- Flow meter to measure water flow rate

- Water source with sufficient pressure and flow rate

- Hose couplings and adapters to connect the hose to the water source and pressure gauge

- Safety valve or relief valve to prevent over-pressurization

Conduct of Hose Testing

Hose testing is a crucial procedure to ensure the safety and reliability of fire hoses. It involves a series of tests to assess the hose’s integrity, performance, and compliance with standards.

Pressure Testing

Pressure testing verifies the hose’s ability to withstand the required water pressure without rupturing or leaking. The hose is connected to a water source and subjected to increasing pressure, typically starting at 100 psi and gradually increasing to the rated pressure of the hose.

Potential test failure:A hose that fails the pressure test may have weak spots, manufacturing defects, or damage caused by improper handling or storage.

Flow Testing

Flow testing measures the amount of water that can flow through the hose under a specified pressure. This test assesses the hose’s hydraulic performance and ensures that it can deliver the required flow rate for firefighting operations.

Potential test failure:A hose that fails the flow test may have blockages, constrictions, or internal damage that restrict water flow.

Visual Inspection

Visual inspection involves a thorough examination of the hose for any visible defects, damage, or wear. This includes checking for cracks, cuts, abrasions, loose fittings, and any other abnormalities that could compromise the hose’s integrity.

Potential test failure:A hose that fails the visual inspection may have been subjected to excessive stress, improper handling, or environmental damage.

Interpretation of Test Results: Nfpa 1962 Hose Testing Procedure

Interpreting the results of hose testing is crucial for ensuring the safety and reliability of fire hoses. The test results indicate whether the hose meets the performance standards and can be safely used for firefighting operations.

Criteria for Passing or Failing

The criteria for passing or failing a hose test are clearly defined in NFPA 1962. The hose must meet the following requirements:

- Withstand the specified hydrostatic test pressure without leaking or bursting.

- Exhibit no visible signs of damage or deterioration.

- Meet the minimum flow rate requirements at the specified test pressure.

Actions Based on Test Results

Based on the test results, the following actions should be taken:

- Passing Hose:Hoses that pass the test can be returned to service and used for firefighting operations.

- Failing Hose:Hoses that fail the test should be removed from service and repaired or replaced.

- Borderline Hose:Hoses that exhibit marginal performance during testing may require further evaluation or reduced-service use.

Record Keeping and Reporting

Accurate record keeping is crucial for hose testing to ensure compliance, maintain a history of hose performance, and facilitate future reference. These records serve as evidence of testing procedures and results, providing a basis for decision-making and liability protection.

The following information should be included in hose testing records:

- Hose identification (e.g., manufacturer, model, size, length)

- Test date and time

- Test location

- Test equipment used

- Test procedure followed

- Test results (e.g., pressure, leakage, elongation)

- Pass/fail determination

- Any repairs or modifications made to the hose

li>Test personnel

Sample Hose Testing Record Template

A sample template for hose testing records can include the following:

| Field | Description |

|---|---|

| Hose ID | Manufacturer, model, size, length |

| Test Date | Date and time of testing |

| Test Location | Where the testing was conducted |

| Test Personnel | Name(s) of personnel performing the test |

| Test Equipment | Type and calibration status of equipment used |

| Test Procedure | Standard or method followed for testing |

| Test Results | Pressure, leakage, elongation, and any other relevant measurements |

| Pass/Fail | Determination of whether the hose meets the acceptance criteria |

| Repairs/Modifications | Any repairs or modifications made to the hose |

| Notes | Additional comments or observations |

FAQ Overview

What is the purpose of the NFPA 1962 hose testing procedure?

The NFPA 1962 hose testing procedure provides standardized guidelines for testing fire hoses to ensure their integrity and performance.

What types of hose testing are covered by NFPA 1962?

NFPA 1962 covers pressure testing, flow testing, and visual inspection of fire hoses.

Why is it important to follow NFPA 1962 for hose testing?

Following NFPA 1962 ensures that fire hoses meet the highest standards of safety and reliability, minimizing the risk of hose failures during firefighting operations.